Siemens uses Virtual Reality for EHS training to prevent accidents

What is EHS?

EHS stands for Environmental Protection, Health Management and Safety. The Governance department at Siemens AG in Germany is responsible for planning, implementing, monitoring and optimizing services and processes. Another focus is the promotion of a resilient health and work culture within the company and together with customers.New ideas needed - the use of Virtual Reality to improve work culture

Virtual Reality (VR) offers a wide range of possible applications, from basic training and employee onboarding to advanced strategies for accident prevention and risk prevention. By using VR, processes can be standardized and optimized. This makes a significant contribution to improving compliance and the health and safety culture in companies.

There is hardly any other area where the advantages of VR can be used to increase value as much as in the area of safety. In everyday work processes, often under time pressure, dangerous situations can fade into the background. This increases the risk of near misses and accidents. In addition to the legally required training, Siemens has looked for a creative way to train its employees.

Virtual Reality enables...

employees to move and interact in a simulated environment. This allows realistic training in handling systems, machines and work equipment.

improved quality of training and increased level of occupational safety, thereby reducing the risk of near misses and accidents.

40-60% time saving when training in VR compared to non-VR training.

a location-independent and collaborative implementation, which increases flexibility.

an effective and efficient method for training new employees and qualifying personnel for machines.

the safe training of work processes. Attention levels are higher and what has been learned can be better internalized than with analog training.

Virtual safety training on aerial work platforms at Siemens

The in-house development of VR training courses offers the significant advantage of tailoring solutions precisely to the specific needs of each department while maintaining independence from external service providers and budget constraints. One challenge remains: Employees must be introduced to the new concepts and integrate them into existing processes. This is where meaningful reference projects and professional advice, which VRdirect provides as part of the collaboration, can help. Once implementation is complete, VR has above-average persuasive power and can save time and therefore costs.

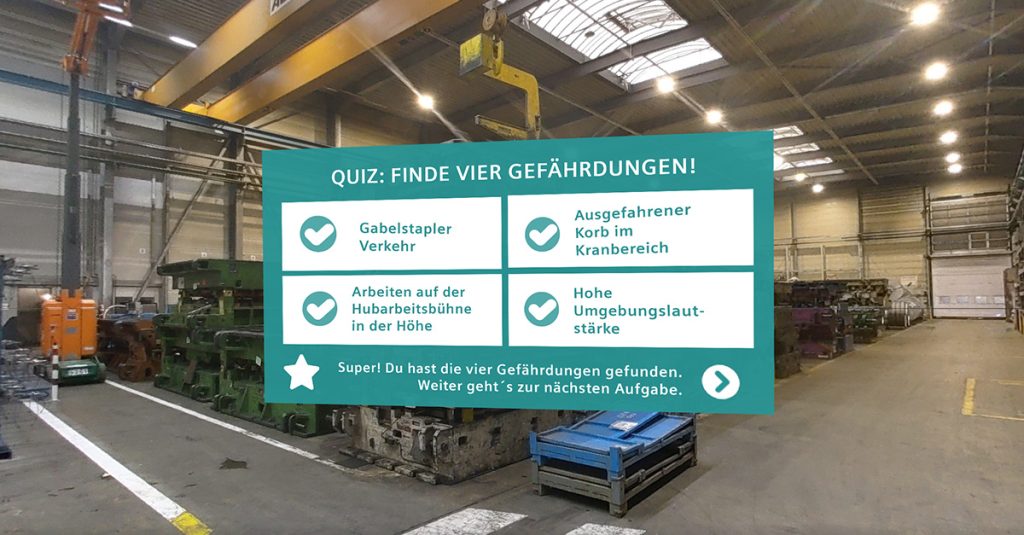

Siemens has now further developed the internal creation of virtual reality training with VRdirect and established it as an initiative. One vivid example is the development of an interactive VR training program for aerial work platforms to prevent accidents. This training provides all the essential precautions and operating instructions required for the safe operation of the work platform. Designed specifically for accident prevention, the virtual reality simulation allows employees to gain practical experience in a safe, controlled environment. Participants go through various modules, which are rounded off with quizzes to reinforce and test what they have learned. By interacting with the virtual scenarios, participants learn to recognize and react appropriately to potential dangers without taking any real risks.

“Employees can create high-quality training courses easily and independently with VRdirect.”

Christoph Supplieth, Central Occupational Safety Specialist at Siemens AG

Thomas Gröger, Safety Expert Siemens AG