The innovative VR tour of the Institute for Machine Tools and Industrial Management (TUM) enables a virtual presentation of the test areas for industry partners

With an innovative VR tour, the Institute for Machine Tools and Industrial Management at TUM has changed its approach to attracting industrial partners. Facing the challenge of efficiently showcasing its extensive test facility, the university partnered with VRdirect to create a comprehensive virtual tour. This VR project successfully replicated the entire test field, providing a lifelike experience of the facility and its research capabilities. The key achievements of this initiative include resource conservation, enhanced accessibility, improved collaboration, and a comprehensive showcase of the institute`s expertise.

This innovative solution exemplifies how technology and innovation can enhance traditional methods, fostering deeper research and industry partnerships.

The Institute for Machine Tools and Industrial Management, located at the TUM School of Engineering and Design in Garching near Munich, faced a challenge in attracting new research and project partners from the industry. Traditionally, they gave potential research partners a tour of their extensive industrial facility, which was both time-consuming and expensive. Furthermore, not all interested parties could visit the facility in person, and certain research areas were inaccessible due to security measures.

Saving time and resources through virtual walkthrough

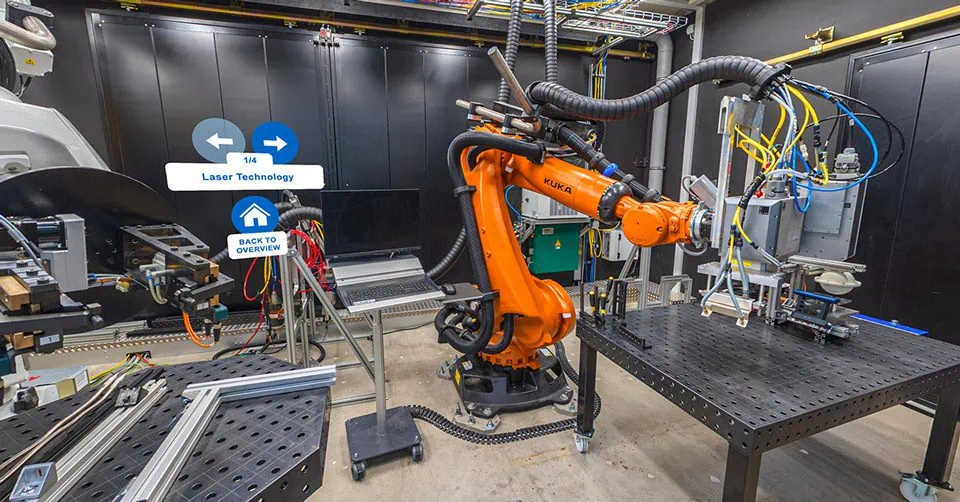

The TUM School of Engineering and Design partnered with VRdirect, the leading Enterprise Virtual Reality software, to showcase its research capabilities and facilities to potential industry partners. They collaborated to create a comprehensive VR tour that provided virtual access to the entire test field. The VR project showcases the university’s industrial hall, where each department or research group has its test setups with industrial equipment. The research of the iwb covers the topics Battery Production, Sustainable Production, Machine Tools, Production Management and Logistics, Assembly Technology and Robotics, Laser Technology, and Additive Manufacturing.

Multiple achievements to increase efficiency

- Virtual Industrial Tour: The VR project successfully replicated the entire test field, showcasing each research group’s experimental setups with industrial equipment. This immersive virtual tour offered a lifelike experience of the facility and its capabilities.

- Resource Conservation: By using the VR tour, the iwb has drastically reduced the need for costly, time-consuming, and resource-intensive physical tours. This significantly improved operational efficiency and cut expenses.

- Accessibility: The VR tour opened doors to potential partners who cannot visit in person, ensuring that no opportunity will be missed due to logistical or safety constraints.

- Enhanced Collaboration: The iwb is now able to share the VR tour with potential partners, providing an initial understanding of their research capabilities. This generated greater interest, and site visits were scheduled for interested parties in the second phase of discussions.

- Security Compliance: The VR project enabled access to otherwise restricted areas while adhering to security protocols – e.g., by eliminating the need for protective clothing and safety training. This ensured the safe exploration of hard-to-reach sections of the test facility.

- Comprehensive Showcase: Beyond the virtual tour through the facility, the VR project also introduces the organizational structure of the institute. Additionally, the research groups presented their expertise, ongoing research, and areas of specialization, promoting a deeper understanding of the capabilities of the iwb.

Benedikt Schmucker, Head of Assembly Technology and Robotics.

Utilization of VR for research and engineering

The iwb has successfully launched an immersive VR tour that represents a significant advancement in its industry collaboration strategy and extends its reach to a broader audience. This innovative VR solution has not only streamlined resource allocation and increased collaboration rates but also serves as an example of how technology and innovation can drive significant improvements in conventional methods, creating new perspectives in research and industry partnerships.